Introduction

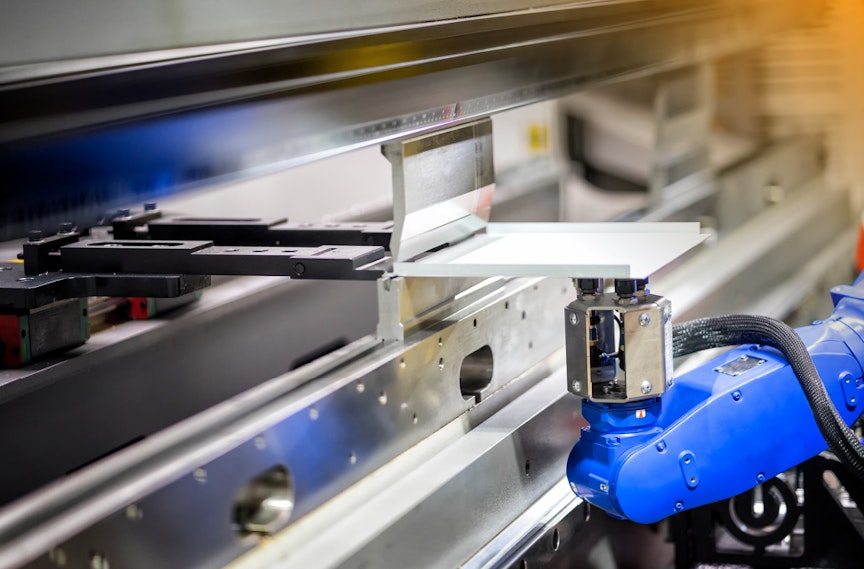

Robotic automation is not a new concept, yet it can be difficult to fully grasp its complexity and overcome its barriers to entry. Which integrator is the best partner for this project? How do you approach your CFO with evidence that you should automate now? What tasks can you even automate? It can be difficult to make sense of all of the technical complexities and varying financial options, especially when you’re already managing other day-to-day responsibilities.

Yet with the current labor crisis, industrial robotics and smart manufacturing is becoming mission critical for all manufacturers. Over 77% of employers face difficulties finding and retaining workers. The question is not if the technology exists: Robotic systems have evolved to include more advanced programming and robot accessories (e.g. gripper systems, vision sensors, robotic arms, etc) over the past few decades. By extension, robots have evolved to fit into a wider range of both additive and subtractive manufacturing applications. The industry’s main challenge is how to reinvent the framework so that all manufacturers, big or small, can have greater access to this technology.

The first step to getting started with robotics is gathering knowledge — demystifying it all by understanding when to automate, what you can automate, and how to get started. There’s a lot at stake: uninformed decisions about industrial robotics could lead to production delays and unnecessary costs. Our first task in this guide is to discover if robotic automation makes sense for you and to explore what it takes to get started. In this whitepaper, leaders and experts in the field will help you navigate through the process.