Should Manufacturers Buy Robots or Use Robots-as-a-Service

We're often asked by manufacturers whether buying their own automation saves them money in comparison with Formic's "Full-Service Automation" model. The answer is: it depends. In some situations buying makes more sense, and others where Formic's usage-based pricing is better.

To help our customers with this comparison, we've put together a framework for answering these questions, along with a case study for a real-world deployment.

Upfront Capital Costs of Buying Robots Outright

When buying automation, we suggest manufacturers consider the total cost of ownership & operation when planning for automation. The important upfront costs to consider are the following:

Equipment and hard assets

The most immediate cost of automation is the cost of equipment & hardware. This usually includes the robot itself, end of arm tooling (EOAT) like a gripper or suction system, vision & sensing systems, safety devices as well as interlocks with other equipment in your facility. These typically make up 50%-75% of the upfront costs of automation.

System integration & programming

All deployments require a degree of customization. This can take the form of engineering hours from your team and integrators, as well as supporting hardware like racks, conveyers etc. This often makes up 25%-45% of the project depending on the complexity of the work.

Safety analysis

Performing risk assessments are critical to ensure the safety of your personnel and equipment. The process of analyzing, identifying, and mitigating hazards can be time consuming and cost up to $10,000 depending on the complexity of the deployment and the severity of hazards identified.

Installation costs

Including delivery and installation, in some cases including foundation work or bolting of hardware. This usually ranges from $5,000-$25,000

Project management and interfacing with vendors

To buy and deploy automation, you'll often have to work with many vendors, and manage the project through its various phases. We've seen customers spend between 50-500 hours to get automation projects installed. This typically incurs a cost of $7,500-$30,000

Ongoing Operating Costs of Buying Robots Outright

In addition to the above, manufacturers should consider the ongoing costs of ownership, with some examples listed below:

Equipment maintenance

All equipment requires regular maintenance - and that is even more true for intelligent systems like robotics. Most manufacturers recommend budgeting 5% - 10% of the project costs per year for maintenance

Replacement parts

If not properly maintained, robots can often require replacement parts (bearings, motors, pendants and more) - typically this costs $2,000-$20,000 per occurrence.

Reprogramming & reconfiguration

Every manufacturing process goes through changes. Often, Formic has seen manufacturers set their robots aside after a process change because reprogramming costs are too high. This typically requires spending $5,000-$25,000 per change depending on the complexity involved.

Unexpected costs

If not properly maintained, a robot cell could go down. When this happens it can cost manufacturers upwards of $50,000 per day. We'll be sharing some examples where deployments have gone wrong for manufacturers in a future blog post so stay tuned!

Case Study:

The example outlined below is for a robot workcell with a "price tag" of $150,000. This is the number a customer would typically be quoted when buying direct from an integrator.

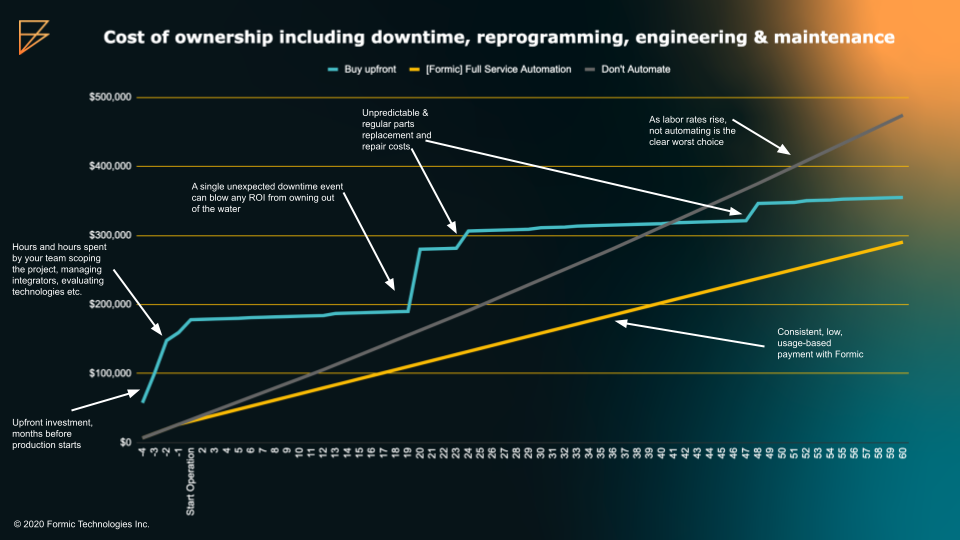

The grey line represents the total cost of operation for a automation system you own. The yellow line represents Formic's "Full Service Automation" solution. With Formic's model, you pay an hourly rate for usage, and that's it. We cover all the other costs, and get the projects deployed with minimal effort from your team. You can find out more about our model here.

When does it make sense to buy your own automation systems?

For facilities which require highly customized systems that they intend to use for 10 years or more, buying their own systems may be a better solution. Alternatively, manufacturers which have large engineering teams dedicated to servicing, maintaining, and programming robots may have a better ROI by buying their own systems (as they have already invested in the costs of the internal resources needed to properly specify, installing and maintaining a system).

Why is it cheaper to use Formic?

Formic provides automation to many customers - as a result, we have economies of scale and can repurpose systems as needed, we can also reduce the costs of installation, service and maintenance because we do this over and over again for many customers. Our scale helps us get better pricing on equipment, services & cost of capital - and we pass those savings on to you. Click here to read about why we started Formic. Additionally for customers who are doing only one (or a few) automation installations it may not make sense to hire the full-time (expensive) automation engineers to properly specify, install and maintain an automation system.

You can also consider the example of a power plant - most factories choose not to run their own generators, it is usually much cheaper to buy power from the grid - because the power plant operates at a larger scale, it is able to reduce the costs for all its users. Formic intends to similarly improve the economics of using automation.

If you're not sure whether buying or using a robot by-the-hour is better for you, reach out to us for a FREE automation consultation, where we will conduct a full ROI analysis based on your situation.

Download the Free Guide: How to Get Started with Robotic Automation

Automating with Formic, the only question manufacturers need to ask themselves is: what repetitive manual tasks can be automated in my facility right now?

More links: