What are automated material handling systems?

What are automated material handling systems, and how do they revolutionize the way goods and materials are handled in various industries? With an increasing demand for efficiency and precision, automation has become a crucial part of today’s manufacturing facilities and warehouses.

Automated material handling systems encompass the use of robotics and automation technology to manage, transport, and organize products within a facility. From palletizer machines to conveyor belts, automation is transforming how businesses operate. Let's explore this fascinating world of automation.

Why Use Robotic Palletizing in Material Handling? A Look at Key Advantages

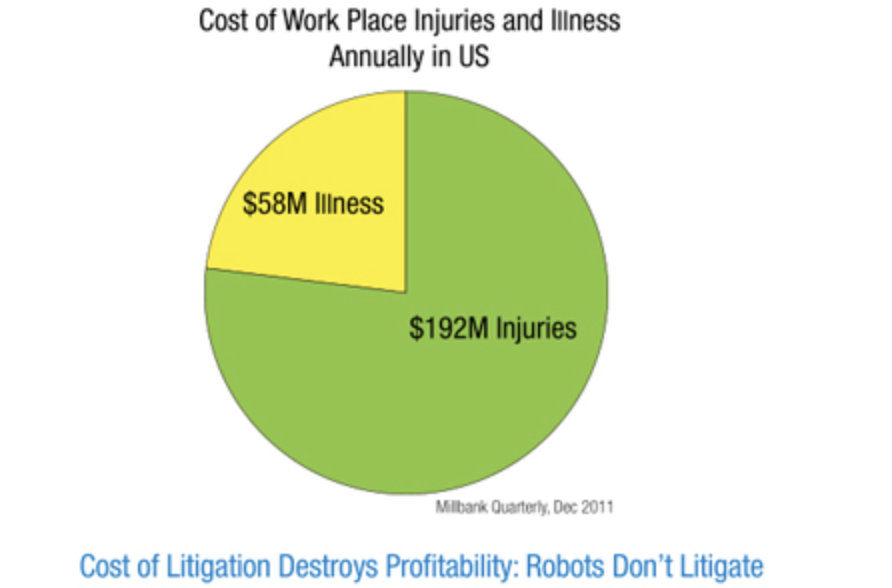

Reducing Worker Injuries Through Automation

Material handling tasks can be strenuous and hazardous. The repetitive lifting, moving, and placing of products can lead to musculoskeletal injuries. Robotic palletizing, part of the automated material handling system, significantly reduces these risks. By delegating heavy lifting to robots, businesses can ensure a safer work environment. The adoption of robotic palletizing at the Ford Motor Company's manufacturing plant helped reduce worker injuries by 70% within the first year of implementation. The automation replaced the repetitive and strenuous tasks performed by employees, resulting in a safer workplace and reducing the related healthcare costs.

Source: Robotics Tomorrow

Integration with Other Material Handling Equipment

Robotic palletizing doesn't operate in isolation. It integrates seamlessly with other material handling machines, including end-of-line packaging machinery. This synergy allows for a more streamlined and efficient workflow, enhancing productivity and reducing operational costs. Nestlé, the world's largest food and beverage company, implemented an integrated robotic palletizing system at its distribution center. The system worked in tandem with the existing packaging and conveyor equipment, providing a seamless transition. The result was a 30% increase in productivity and a significant reduction in operational costs. By allowing the robotic system to handle heavy lifting and repetitive tasks, human workers were free to focus on more complex and strategic roles. Therefore, automated palletizers aren’t just for manufacturers, they’re also a perfect fit for contract packagers and 3rd Party Logistics operations.

Get Your Free Getting Started Guide Here

Automated Material Handling Robots: Top 5 Applications You Should Know

Packing Products with Palletizer Machines

Packing products for shipment is a critical yet tedious task. Palletizer machines, equipped with advanced robotics, simplify this process. These machines systematically pack products onto pallets, preparing them for shipping or further processing, all while maintaining quality and efficiency.

Part Transfer Automation

Moving parts from one area to another may seem mundane, but it's essential in manufacturing. Automated material handling systems, including robotic arms, ensure that parts are transferred accurately and promptly, minimizing downtime and maximizing productivity.

Robotic Loading and Unloading of Conveyors

Conveyors are vital for moving material around a facility. But what about loading and unloading products onto them? Robots come into play here, handling tasks like automatic pallet shrink wrapping and placing products onto conveyors, ensuring smooth operations.

Integrating Robotic Palletizing into Your End of Line Packaging Machinery

Robotic palletizing is no longer a futuristic concept; it's a present-day necessity. Integrating robotic palletizing into your end of line packaging machinery can revolutionize how products are prepared for shipment. From precise stacking to automatic pallet shrink wrapping, robotic palletizers are designed to handle complex tasks with ease. This integration not only enhances efficiency but also ensures consistency and quality in packaging. Learn how to seamlessly integrate robotic palletizing into your existing machinery and elevate your packaging process to the next level.

Embracing RaaS for Enhanced Automated Material Handling in Your Facility

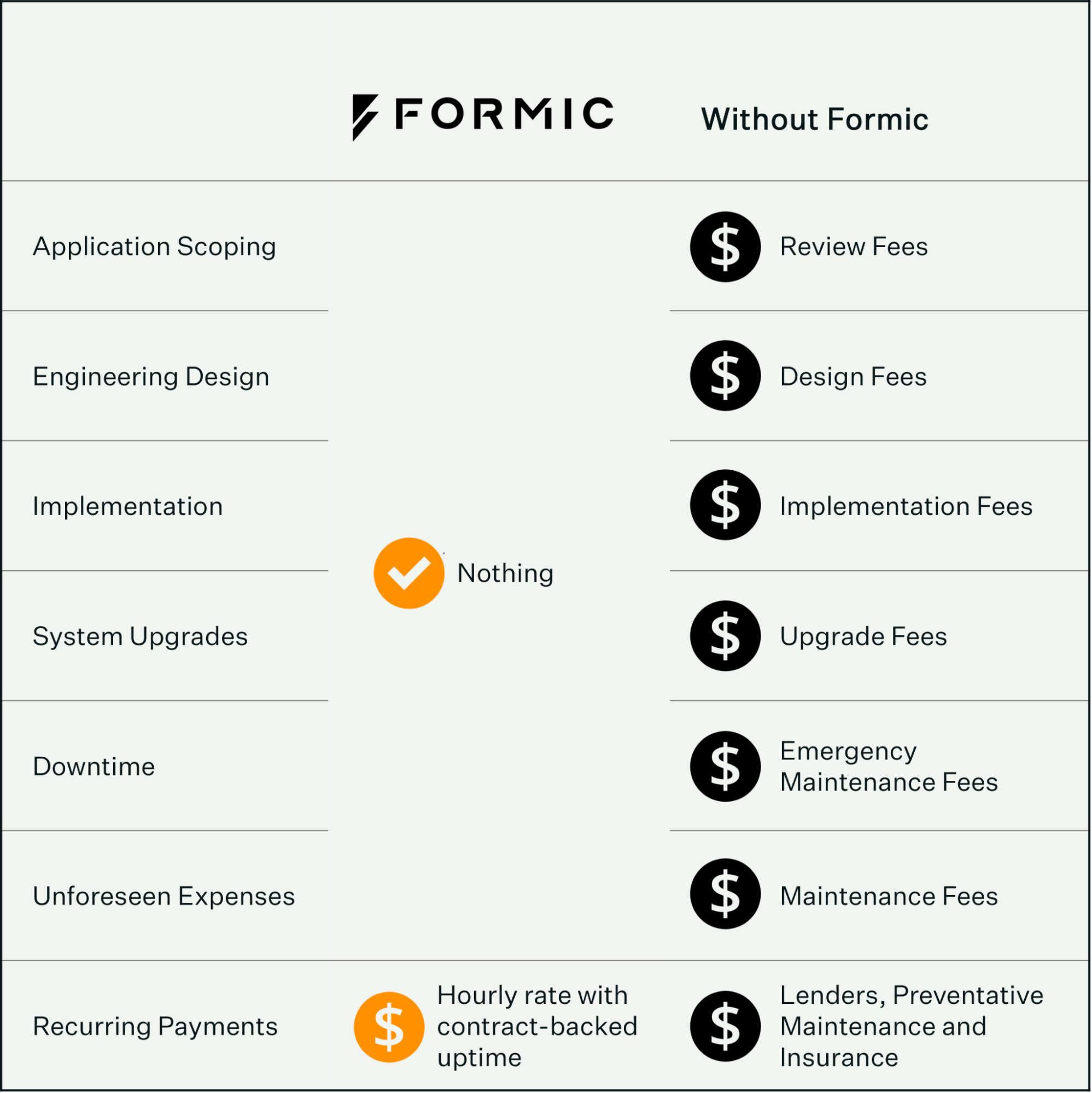

Robotics as a Service (RaaS) is transforming the way businesses approach automated material handling. By offering robotic solutions on a no upfront cost, low hourly rate basis, RaaS makes it accessible and cost-effective to integrate advanced technologies like palletizer machines and end of line packaging machinery.

Source: Formic.co

Formic’s RaaS model eliminates the worries around proposing huge capital investments at budget meetings, removes worries about system maintenance and training, and last but not least, removes the dependency on the unreliable labor markets. By embracing RaaS in automated material handling, businesses can leverage cutting-edge technology in a financially sustainable manner, aligning with both current operations and future growth strategies.

Download the Free Guide: How to Get Started with Robotic Automation

Automating with Formic, the only question manufacturers need to ask themselves is: what repetitive manual tasks can be automated in my facility right now?