How to Get Started With Robotic Automation in Your Facility: A Guide by Formic.co

Integrating robotic systems into manufacturing workflows offers efficiency, precision, and productivity. Industrial robotics used to be way too expensive, complex, and risky for smaller manufacturers, but due to increasing technical flexibility, education, and usability, we’re seeing an era of unprecedented adoption. With automation, manufacturers are able to produce more, reduce operating costs, and drastically reduce workplace injuries.

This guide will help you begin the process of automating your production and packaging lines.

Introduction: Why Automate Now?

Navigating Labor Shortages

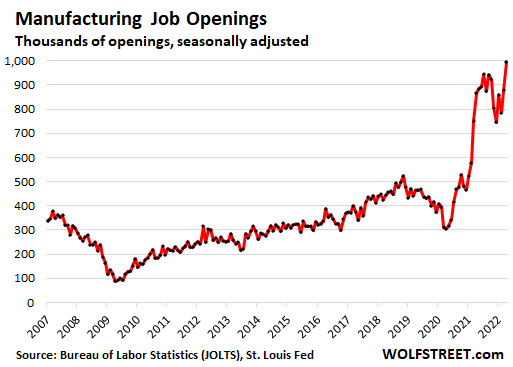

The current landscape of the manufacturing industry is characterized by a notable labor crunch. On one side, baby boomers are retiring, leading to a dearth of experienced workers. On the other side, the manufacturing sector grapples with filling these gaps, particularly in skilled positions that require specialized expertise. This situation has catalyzed the shift towards manufacturing automation as a strategic response to these labor challenges.

Today's robotic systems are not only more sophisticated but also more adaptable and cost-effective than their predecessors. These advancements have democratized access to manufacturing automation, enabling businesses of various sizes and capabilities to integrate robotic solutions into their operations. These advancements have put robotics in a position to fill this labor gap in previously improbable ways.

From Luxury to Necessity

What was once considered a tool for only the largest and most sophisticated manufacturers has now become an indispensable tool in the manufacturing toolkit for companies of all sizes. It's no longer just about staying ahead; it's about staying relevant and viable in an increasingly competitive and globalized marketplace. Manufacturing automation offers a pathway to address these challenges head-on, promising enhanced productivity, reduced costs, and the ability to maintain a competitive edge in a rapidly evolving industry.

Staying Ahead of Global Competitors

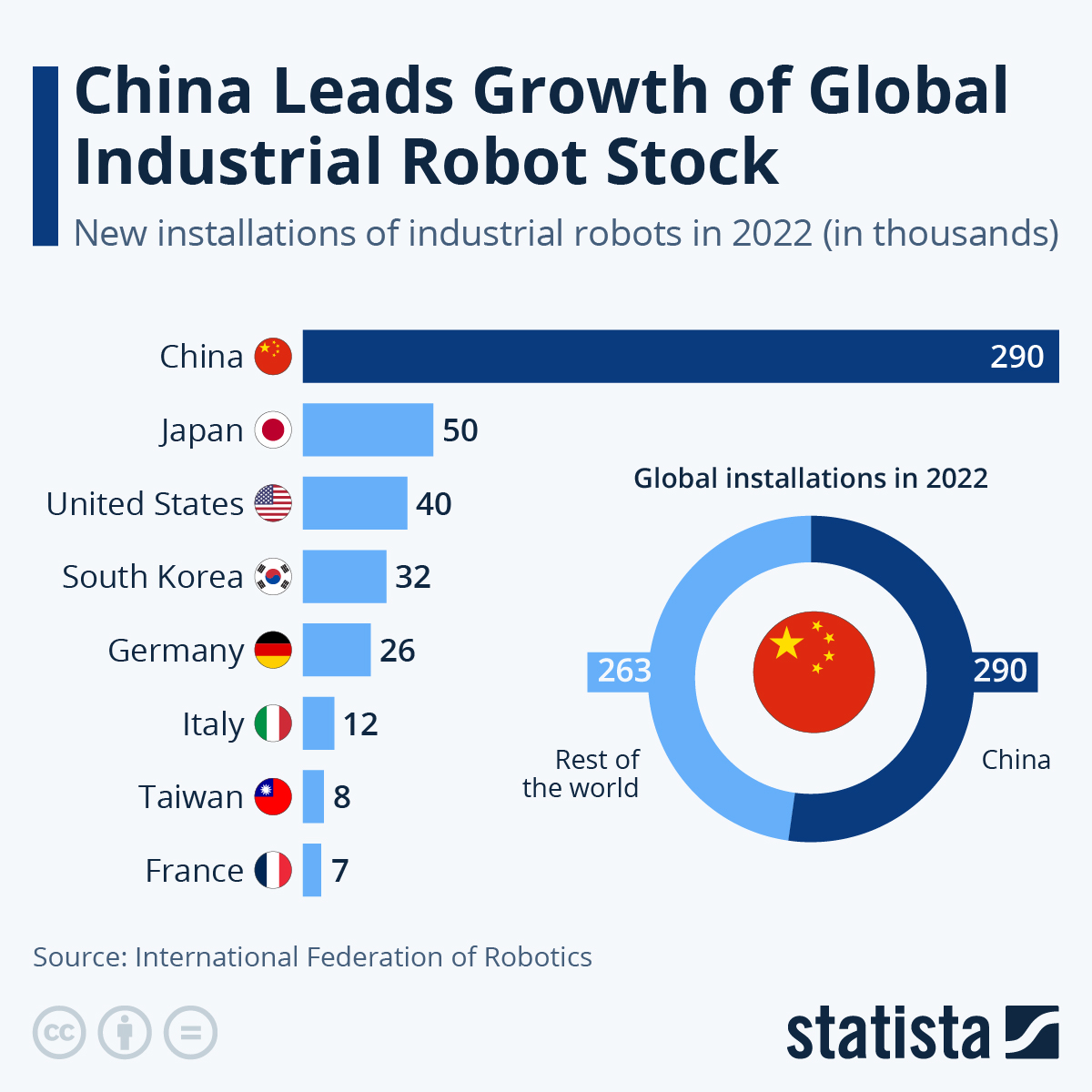

In today's global economy, competition in the manufacturing sector is fiercer than ever. Companies worldwide are rapidly adopting automation to enhance their production capabilities and efficiency. This global trend underscores the importance of manufacturing automation in maintaining competitiveness. Companies that hesitate to adopt these technologies risk falling behind in efficiency, quality, and innovation. Manufacturing automation is a strategic imperative to remain viable and competitive on the global stage.

The convergence of labor shortages, technological advancements, and intensifying global competition creates a compelling case for the immediate adoption of manufacturing automation. The time for automation is now, not just as a means to enhance efficiency but as a crucial strategy for survival and growth in the modern manufacturing landscape.

Part 1: Identify the Right Processes for Automation

Tasks that are repetitive and predictable are prime candidates for automation. These processes often involve manual labor that is monotonous and, in some cases, ergonomically challenging for workers. Automation in such areas not only boosts productivity but also enhances worker safety by reducing the risk of repetitive strain injuries.

Another consideration is the level of manual dexterity required. Tasks that involve complex manipulations or require a high degree of precision are often challenging to automate. However, with advancements in robotics, even these tasks are becoming increasingly feasible for automation.

While there is no “one size fits all” approach, there are common starting points for automation within manufacturing based on industry.

Get Your Free Getting Started Guide Here

For producers of fast-moving consumer goods (food, produce, beverages, pharmaceuticals, cosmetics, etc.), end-of-line material handling automation such as case sealing, palletizing, stretch-wrapping, and material transportation are common places to begin on an automation journey, as they can be implemented without significant implications on up or downstream processes.

From there, companies typically move upstream on the production line to more complex automation challenges such as sorting, case packing, labeling, and more.

For manufacturers working with metal, automation scoping is typically centered around individual processes and machines. For instance, robotic welding has revolutionized the way metal components are joined, offering unparalleled precision and consistency. Any discrete machining can typically be automated with a machine load/unload, whether that machine is turning, drilling, milling, planing, or sawing.

Identifying the right processes for automation is a critical step in the journey towards manufacturing automation. By strategically selecting tasks that are best suited for robotic intervention, manufacturers can reap the full benefits of automation, including increased productivity, enhanced safety, and improved product quality. This section underscores the importance of a thoughtful and targeted approach to integrating automation into manufacturing processes.

Part 2: Choose a Financing Path

Exploring Financial Avenues for Manufacturing Automation

In the world of manufacturing automation, figuring out how to finance your technological leap is a critical step. It's not just about picking the right robots, but also about choosing a financial path that aligns with your company's goals and budget. Let's walk through the options available, understanding their nuances and implications.

Direct Purchase: The Upfront Investment Approach

Starting with the traditional route, direct purchase requires a significant upfront investment. You get full ownership and no worries about future payments. But, this approach demands substantial capital, which can be a heavy load for small to medium-sized enterprises. Plus, you're on the hook for all future maintenance and upgrades, which adds to the long-term costs. And don't forget about the risk of your new tech becoming outdated – a challenge you'll have to navigate as technology evolves. Some purchases may qualify for relevant tax breaks.

Get Your Free Getting Started Guide Here

Financing: Spread Your Capital Dollars

For businesses that want a robotic system but also want to preserve their capital, financing is a great option, however, high interest rates will ultimately lead to a higher overall system cost. Similar to purchasing, companies will typically be responsible for handling their own system monitoring, maintenance, and upgrades. Companies will typically need to put money down on a system before it is operational and on their facility floor.

Leasing: Financial and Operational Flexibility

Think of leasing like renting – you get to use it, and typically you’re responsible for maintenance of the system . You will need to pay for the system before it is on your floor. Leasing is great for companies with in-house engineering talent that want to just use a system for a limited time. Over time, leasing can end up costing more than buying.At the end of the lease, you'll face choices: renew, buy, or upgrade. Each option comes with its own financial implications and decisions to make.

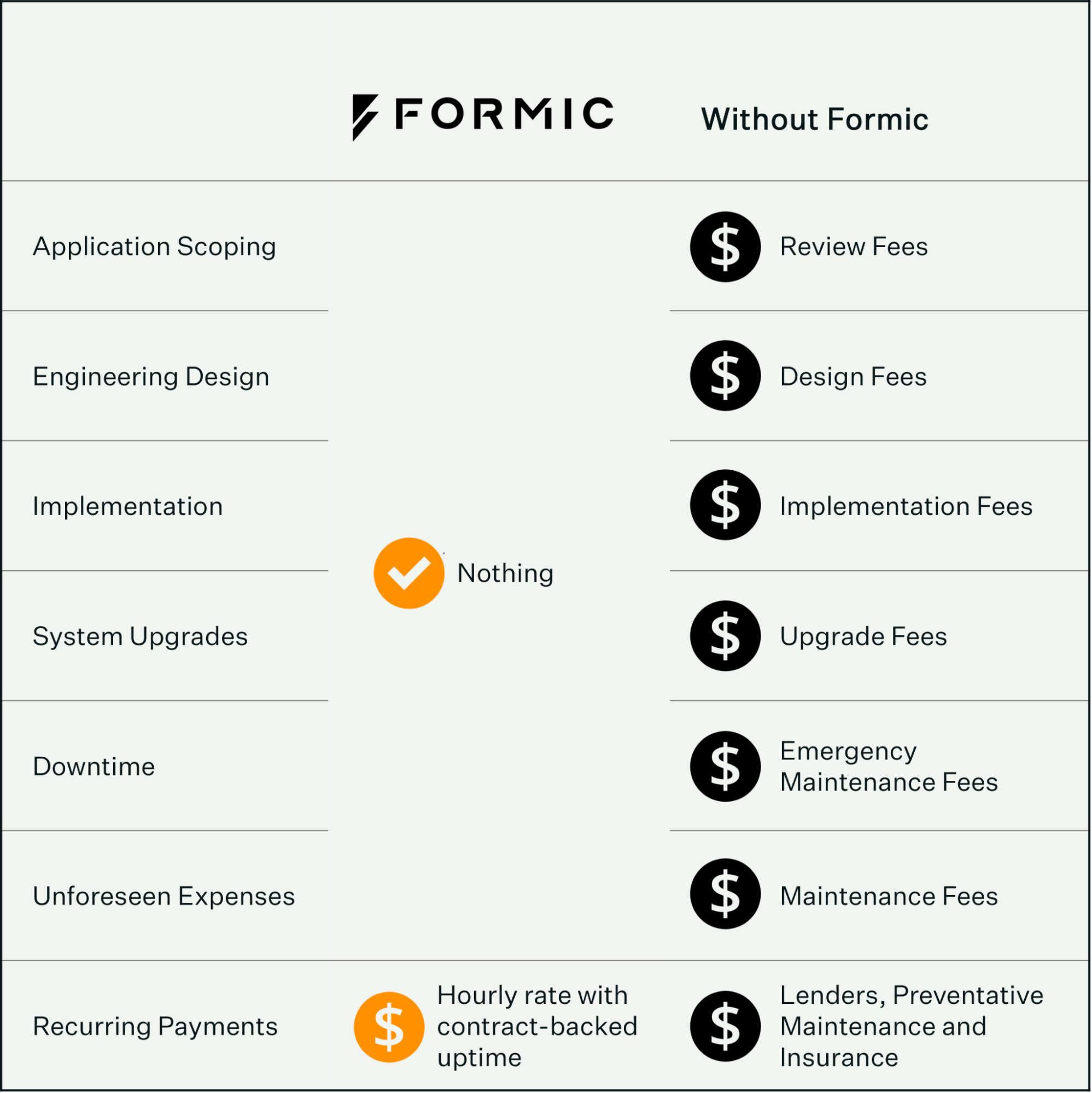

Robotics-as-a-Service (RaaS): Automate The Easy Way

Robotics-as-a-Service (RaaS) model is a more modern approach that's changing the way manufacturers automate. RaaS simplifies the process by offering not just the installation, setup, and use of robots, but also their maintenance, updates, and support. It's like having a robotic workforce at your fingertips without the hassle of ownership or the stress of upkeep.

Choosing the Right Path for Your Business

So, how do you decide? It boils down to your company's financial health, capital availability, production planning, and long-term strategy. Consider how much capital you're willing to invest upfront, and think about your strategy for growth and adaptation. Are you ready to commit to a big purchase, or does the flexibility of leasing align better with your future plans? Remember, each option has its strengths and challenges, and the right choice depends on your unique business needs and goals.

Get Your Free Getting Started Guide Here

The Process of Implementing Automation

Avoiding Common Pitfalls in Automation Deployment

Regardless of the chosen method, there are common pitfalls that businesses should avoid. One major mistake is poor communication – both within the company and with external partners. Clear, consistent communication ensures that everyone is on the same page and that the integration of automation aligns with the company's objectives.

Another potential issue is changing application requirements mid-implementation. Some adjustments to robotic cell requirements are trivial. Others may seem trivial but can have critical hardware and/or software repercussions. It's essential to have a well-thought-out plan before starting and to stick to it as closely as possible. Frequent changes can lead to delays, increased costs, and even project failure.

Real-World Example - Compact Industries' Automation Journey

Transforming Palletizing Operations: A Tale of Innovation and Adaptability

Compact Industries is a family-owned business, specializing in food and beverage packaging, that faced a shrinking labor pool and the escalating demands of a competitive market.They had no experience with robotic automation but were interested in getting started.

The Challenge: Navigating Labor Shortages and Rising Demands

Compact Industries, like many packaging companies, was growing but found itself hamstrung by high worker turnover, labor shortages, and the relentless pressure of inflation. These challenges threatened their ability to meet the needs of their Fortune 500 clientele. The company needed a solution that would not only address these immediate issues but also set them up for future success.

The Automation Leap: Embracing Robotic Palletizing

Compact Industries and Formic deployed a fully-integrated palletizing system, featuring a collaborative Yaskawa robot.

The Impact: Quantifying Efficiency and Flexibility Gains

Compact Industries' journey into automation improved their operational efficiency and flexibility. The system can lift 35 lbs per pick and handling up to 6 cycles per minute, which brought productivity to new heights, delivering an impressive 720 cases per hour.

Recognizing the immediate benefits, Compact Industries didn't hesitate to double down on this success. Within just a month of deploying their first system, they ordered a second one, unlocking even greater productivity potential. This rapid expansion was a testament to the effectiveness of the automation solution, made feasible within their capital budgets and resource constraints. The company's embrace of their robotic helpers went beyond functionality; they even personified their efficiency-boosting robots, affectionately naming one "Rosie," a nod to their integral role in the company's growth.

Get Your Free Getting Started Guide Here

Preparing for Implementation - Key Questions and Considerations

Setting the Stage for a Smooth Automation Transition

As businesses like Compact Industries have demonstrated, the decision to implement manufacturing automation is transformative. However, preparing for this change involves more than just selecting the right equipment. It requires thoughtful consideration and planning to ensure a seamless integration into existing operations.

Critical Considerations Before Implementing Automation

Before embarking on the automation journey, there are several key questions and considerations that businesses must address:

-

Understanding Operational Needs:

What are the specific goals and objectives of automation? Businesses need to identify the processes that will benefit most from automation and how these changes align with their overall operational strategy.

-

Evaluating Technical Requirements:

What are the technical specifications required for the automation solution? This includes understanding the capabilities of different robotic systems, space requirements, and compatibility with existing machinery.

-

Assessing Workforce Implications:

How will the introduction of automation impact the current workforce? It’s crucial to plan for training and retraining, reallocation of staff to other roles, and managing any changes in workforce dynamics.

-

Financial Planning:

Beyond the cost of purchasing or leasing equipment, what are the long-term financial implications? This includes maintenance costs, potential upgrades, and the return on investment timeline. -

Partnering with the Right Provider:

Choosing a provider like Formic, which offers comprehensive solutions and support, can be crucial to the successful implementation of automation.

The journey towards manufacturing automation is as much about strategic planning and preparation as it is about technology. By addressing these critical considerations, businesses can lay a solid foundation for integrating automation, ensuring that the transition is not only successful but also aligns with their long-term operational and financial goals.

Download the Free Guide: How to Get Started with Robotic Automation

Automating with Formic, the only question manufacturers need to ask themselves is: what repetitive manual tasks can be automated in my facility right now?