Palletizing and depalletizing have quickly become two of the most popular tasks to automate in factories and warehouses. Why the sudden explosion?

For one, the need is universal. Almost every manufacturer has some form of shipping and receiving in their operation.

Also, the tasks are ideal for automation. Moving heavy boxes and goods around, which is what palletizing and depalletizing is, fits perfectly into the “dull, dirty, and dangerous” category of jobs that are horrible for humans and great for robots.

Although these applications are common, they are not always easy to implement. The sections below provide brief overviews of each and highlight some of the key differences when implementing robotic automation.

Background: What’s the difference between palletizing and depalletizing?

Palletizing is the act of loading materials onto a pallet, whereas depalletizing is the unloading of goods from a pallet onto part of a production line. One is typically for outbound shipment while the other is for inbound receiving. Although they are both picking and placing items, there are unique challenges and requirements for each one due to the differing processes and constraints.

The Key Factors in Robot Palletizing

Robot Palletizing System

The three key design factors for robot palletizing are material, arrangement, and speed (cycle time).

Material: The material, or object, being handled is always one of the first things to consider. The material determines the robot arm, gripper, and vision sensor.

Is the robot going to be handling a box, a case, a bag, or some mix of those? What are the dimensions? Are some objects semi-translucent and difficult for sensors to “see"? For mixed SKU productions, is packaging color the differentiator between SKUs? These questions largely determine the robot arm, gripper, and vision sensor.

- Arm: Determined by payload, reach, and speed

- Gripper: Determined by the object being grasped

- Vision sensor: Determined by working distances, accuracies, and color capabilities

Arrangement: Arrangement is how the objects are arranged on the incoming conveyor line and how objects need to be placed on the pallet. Can they be placed anywhere? Or is there a specific placement plan? Also, many factories require slip sheets on the pallet and between certain stages of stacked goods. These requirements will determine the type of gripper and the application’s level of sophistication.

Speed: Throughput is always a top consideration for automation, but especially for palletization, where material is exiting the end of the production line. An issue with the palletization station could be a significant problem if it causes upstream back ups. This is why the cycle time, which is predominantly related to application reaction time and robot arm speed, is so important.

The Key Factors in Robot Depalletizing

Robot Depalletizing System

Depalletizing is essentially rewinding the palletization task - Objects are picked up from a pallet and put onto part of the production or handling process.

For depalletizing, speed is still important, but material and pallet arrangement are much more critical. Depalletizing can present more unique challenges that are not relevant to palletizing.

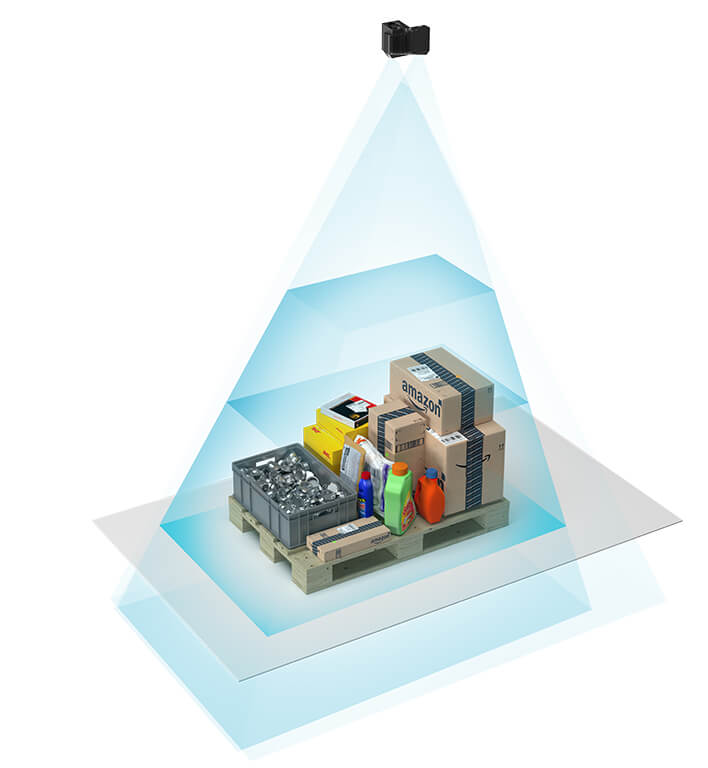

Mixed SKU Depalletization - Image source: Zivid 3D Vision, www.zivid.com

Material: Similar to palletizing, the material largely affects the robot selection, the gripper, and the sensors. However, there are also extra and unique complexities. Incoming pallets often contain objects that are wrapped in shrink wrap. This can be challenging for many 3D sensors to accurately see, which then affects picking reliability.

Also, does the pallet contain a mix of several SKUs or one single SKU? “Mixed SKU” depalletizing is much more challenging and typically needs sophisticated robot applications, like Plus One Yonder or Mujin’s depalletizing solution. (Note: These are a couple examples, but Formic is a brand-agnostic solution provider and our speciality is sourcing and financing the right solution for your application).

Lastly, size of objects can become a factor at the bottom of the pallet because sensor and grasp errors increase as the working distance from the sensor increases. For example, 2% sensor error at 3m is common, so the object’s true location can easily be distorted by 30 or more centimeters. This results in a mispick or crashing the robot into unwanted objects.

Arrangement: Arrangement of goods can also be more challenging for depalletizing than it is for palletizing. One common challenge in factories is when incoming boxes are tightly packed together on the pallet, which is rarely an issue for palletization. In this scenario, vision sensors and applications often falsely detect two boxes as only one. This can result in improperly picked items, and ultimately, dropped items.

Have no fear, thousands of successful applications deployed

If you’re considering automation for palletizing or depalletizing, don’t worry - Design challenges are typical in any engineered system. The good news is that thousands of robot palletizing and depalletizing systems have overcome these challenges and they are now fielded and proven. We’re confident that your application is also feasible.

The main questions you need to consider to get started are:

- Do your volumes justify automation? (is it at least a 1 shift operation?)

- What objects are you handling?

- Is it only one SKU and dimension or several SKUs and dimensions?

- What are your physical space constraints?

- How are you going to finance your system?

Your answers will lay the foundation for your new automation. Formic can help with answering the “how” to make it happen. Contact us today for a free consultation.

If you are an integrator and interested in joining our certified partner network, apply here.

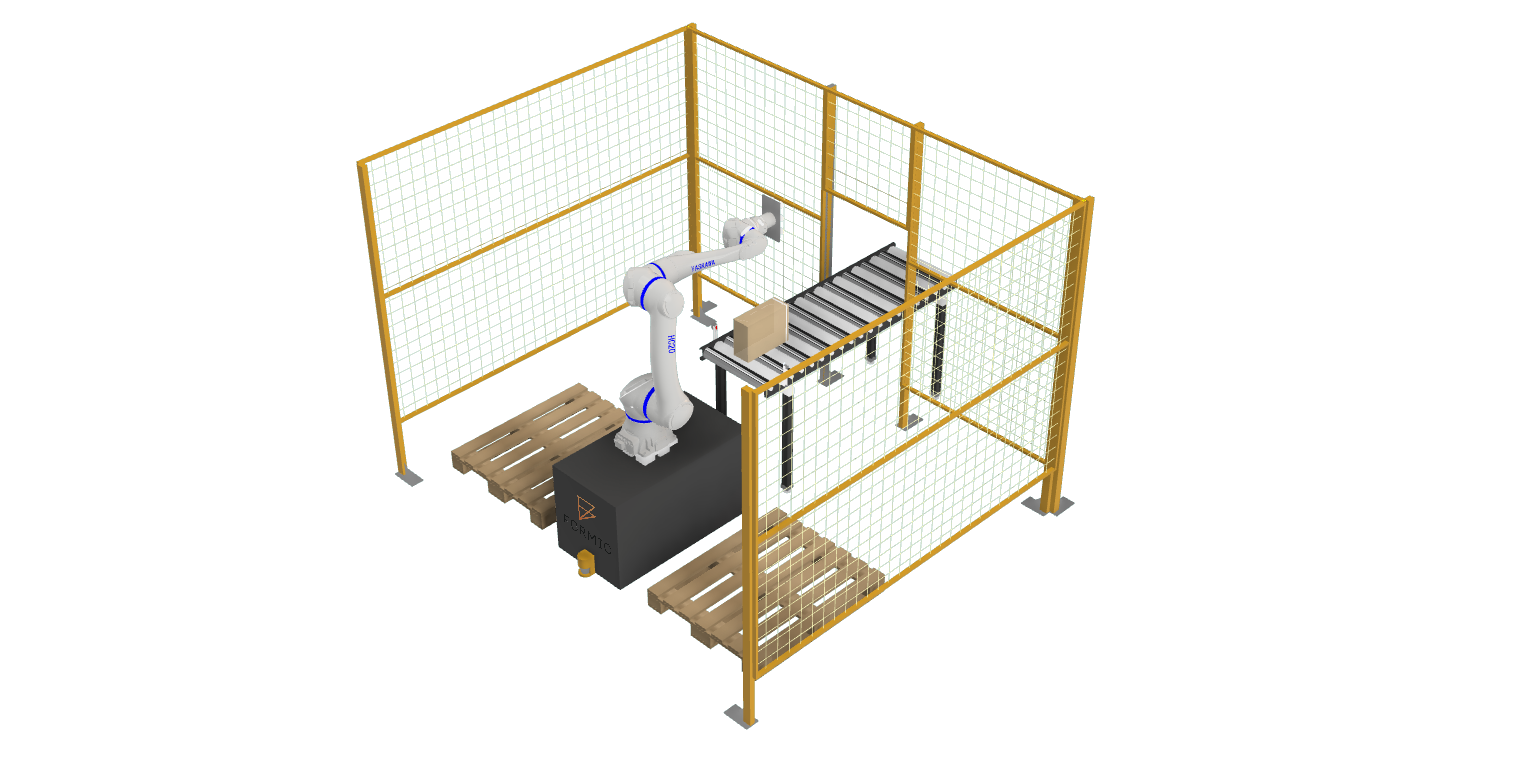

Formic solution example for Robot Palletizing