Formic helped revolutionize Compact Industries' production process, jumpstarting their automation journey. In record time, the 1963-founded food and beverage packaging specialist went from delivery to palletization with a collaborative robotic system – ushering in unprecedented productivity and efficiency gains for the company.

The Challenge

"We were driven towards robotics to maintain a high level of quality and consistency for our products, but very low labor retention has been absolutely the biggest challenge," said Tracey Miller, Compact’s Senior Vice President.

Like many U.S. packaging companies today, Chicago-based Compact Industries has been growing quickly but amid the challenges of a shrinking labor pool, high worker turnover, and supply and wage inflation, this family-owned business was struggling to meet the increasing demands of the Fortune 500 companies it serves.

The manufacturing industry as a whole has significantly suffered due to a lack of manpower. 8 in 10 manufacturing executives have reported that labor shortages are having a major impact on their ability to deliver what is promised, and job openings in the sector over the last year consistently exceeded pre-pandemic numbers - clocking a staggering 877,250 openings throughout this year alone.

With such a dire labor situation, Compact’s managing team recognized the need to automate but was cautious following a negative experience buying and managing automation on their own.

“What attracted me to Formic was the low risk,” said Rich Moldovan, Compact’s Engineering Manager. “With big decisions like this, you're putting your reputation on the line, but I felt very confident with Formic. The whole process was so seamless, and this quality of service didn’t happen when we tried to automate on our own.”

Moldovan continued, “We have some associates placing boxes on pallets for an entire 10-hour shift and we don’t want them straining or getting injured. Our employees are a key part of our success. And what’s great about robots is they don’t quit or get injured.”

The Solution

After evaluating Compact’s needs, requirements, and constraints, Formic partnered with SourceLink Solutions to design and deploy a fully-integrated mobile palletizing system that includes a Yaskawa collaborative robot. The system decreases Compacts’ reliance on temporary labor and their need to constantly retrain workers, while also promoting their staff to more ergonomic tasks therefore unlocking the factory’s full potential.

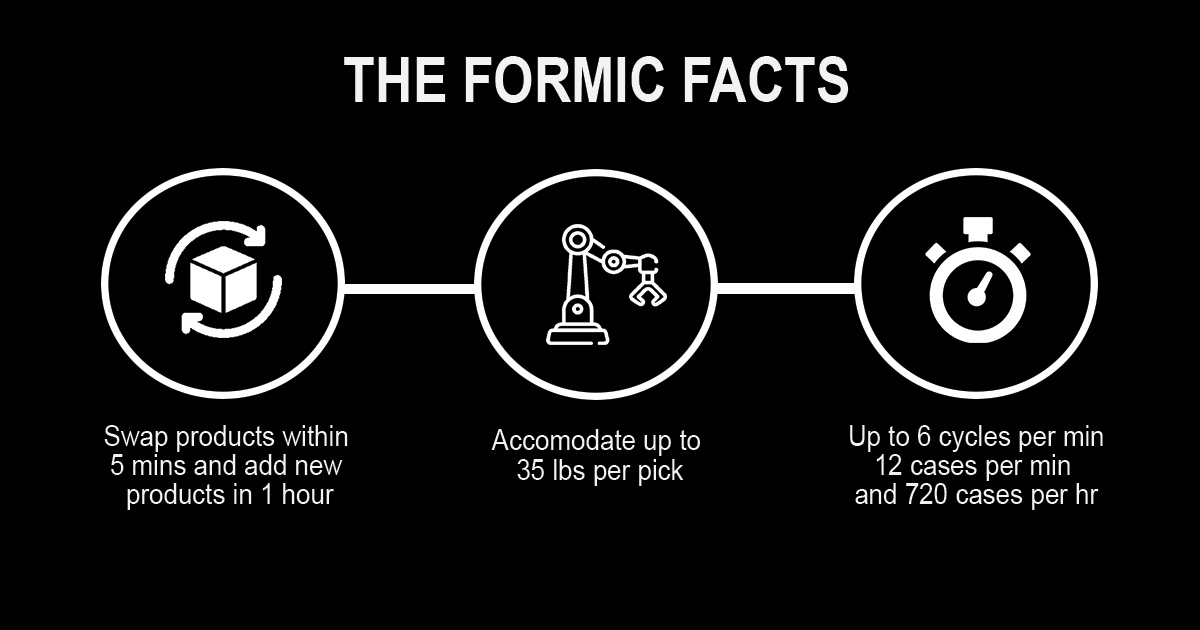

The current system delivers unprecedented efficiency and flexibility to Compact’s daily operations. With impressive lift capabilities of 35 lbs per pick and the capability of handling up to 6 cycles a minute, this robot boosts productivity by delivering 720 cases per hour! Any product changes can occur swiftly; switching from task to task requires just 5 minutes while adding new products only takes about one hour.

Within one month of deploying the first system, Compact ordered a second system, unlocking new productivity potential that was impossible with traditional capital budgets and resources. In fact, Compact has such a fondness for their robots, they've decided to name them! Check out "Rosie" below.

Get Your Free Getting Started Guide Here

“Robotics is extremely fragmented, which means there’s no clear supply chain for hardware and machine builders are often reinventing the wheel,” said Formic’s Co-founder and VP of Solutions and Partnerships, Misa Ilkhechi. “In building a fleet of rental robots, Formic is also building this massive library of automation solutions that can do everyday tasks, so we don't have to reinvent the wheel every time. We’re also resolving the supply chain issue and lowering costs by creating a platform where we purchase hardware in bulk.”

As a specialty packager of coffee and tea for one of the country’s largest brands, the productivity gains that Compact made with Formic’s automation solutions continue to fuel the engine of American work by helping to ease supply chain issues and ensure that consumers are getting the products they want and need in a timely manner.