Mi Rancho has been delighting customers with authentic and fresh tortillas, chips, and salsas since its establishment in 1939. Originally founded as a grocery store in Oakland, California the business has evolved and grown into a food provider for large nation-wide retail partners. Today, the company operates from their 150,000 square foot facility in Elk Grove and is growing more than 40% year-over-year thanks to rapidly advancing their operations to keep up with market demand.

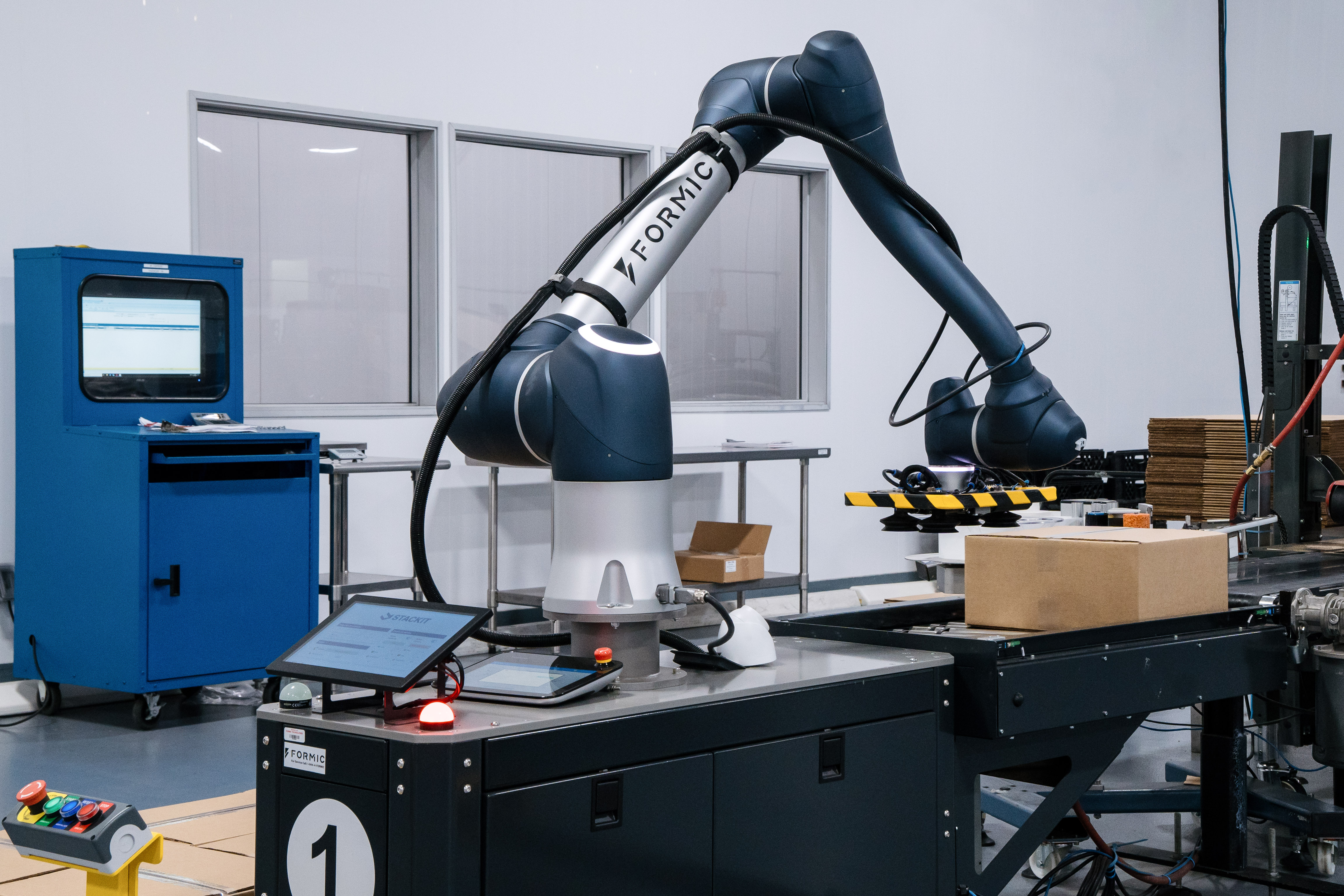

To enable their continued growth, Mi Rancho recently partnered with Formic to introduce robotic automation to their food processing and packaging production operations.

With Formic, Mi Rancho automated six of their end-of-line palletizing stations, helping their team to:

- Instantly increase productivity, quality, and safety on their production lines without additional headcount costs that come with traditional automation purchases

- Eliminate manual stacking injuries and dependency on hard-to-find labor

- Achieve immediate ROI and efficiency with zero capital investment

The Challenge

Mi Rancho produces millions of pounds of goods per year and is experiencing double-digit year-over-year growth. With that scale of production comes the challenges of streamlining their efficiency, safety, and costs for their customers and their employees.

Joe Santana, Mi Rancho’s Senior Director of Operations, has been part of the Mi Rancho operations team for 20 years and has the critical role of overseeing all facets of their operation. As their business has grown, Joe and his team have been encountering more and more challenges related to finding and retaining reliable labor and improving employee safety.

“We do a lot of lifting”, said Santana. “We have a lot of manual labor and safety is a huge concern of ours. But it's also not easy to hire or to find personnel. The workers are just not out there.”

With a growing number of boxes being stacked every day across three shifts, Santana and the Operations team set their sights on robotic automation to help overcome both labor safety and production reliability challenges.

“We want people to come to work, and we want them to go home wholesome”, said Santana. “We don't want them to be injured, and so the only way to protect them is if we find other ways to do the job. Lifting boxes is something that robots can easily do.”

Although the benefits of automation were clear, getting capital budget approval was not easily available. The purchase request for end-of-line robotic palletizers was competing with a long list of other capital intensive growth projects.

The Mi Rancho team was in a situation that is common to thousands of other small and mid-sized manufacturers - they identified the need for automation to grow their business, but lacked the capital budget, robotics experience, and internal resources to deploy it and maximize the success.

Solution

The Formic Robots-as-a-Service model perfectly addressed Mi Rancho’s goals and overcame their financial and operational obstacles to make automation an obtainable solution. With zero capital investment from Mi Rancho, Formic specified and deployed multiple collaborative robotic palletizer solutions for Mi Rancho’s four tortilla lines - a perfect fit for their box weights and sizes, throughput requirements, and floor space requirements. Mi Rancho only pays one low hourly rate that includes equipment usage, 24/7 system monitoring and support, 100% maintenance, and continuous upgrades.

After experiencing the success of Formic’s automation solutions and service, Mi Rancho quickly added more systems for their other production lines.

To meet increasing throughput requirements on the Mi Rancho chip line, Formic scoped and deployed an industrial palletizer capable of delivering faster speeds and heavier case weights required to meet demand. Just like the collaborative palletizing solution, this industrial system was also delivered through Formic’s fully supported Robots-as-a-Service program.

Throughout the entire process, Santana and the Mi Rancho team were continuously impressed with the Formic commitment to delivering exceptional service and maintaining top-notch performance after installation - the ongoing support was a big plus for Mi Rancho.

“For us to have robotics and to own robotics, we would have to bring people with that skillset,” Santana shared “But Formic committed to maintain the equipment, to service the equipment, to do all the technical support, and programming and they offered to handle that portion for us. So it became really very attractive at that point.”

Results

Since integrating Formic’s six robotic palletizers into their operations, Mi Rancho has eliminated safety risks with end-of-line stacking and has increased production efficiency by repurposing their team to other value-added jobs.Employee fatigue, breaks that result in downtime, and costly employee turnover have all been reduced or eliminated. What was previously a challenging manual process is now on-demand palletizing at the push of a button.

Santana and the Mi Rancho team have been very happy with the results and experience of working with Formic.

“Formic’s commitment to make a smooth transition and to assist us every step of the way was very helpful and the performance of the equipment has been just like it was predicted”, said Santana. “It’s probably the only project where the supplier said exactly what the process would look like and what the results would be. Formic came through with every aspect of the installation of the project, and the support has been excellent and the communication has been excellent.”

Financially, Formic’s unique model has generated instant savings versus the previous manual workflows. With zero capital costs and the low hourly usage rate, Mi Rancho was able to generate immediate business value.

“We ended up very satisfied with the way that it is structured”, said Santana. “The machine works, and we're paying for it when it works. If it's not active, then there's no charge, and that’s perfect for us.”

Looking forward, Santana sees a world of opportunities for automation and their burgeoning partnership with Formic.

“After seeing the results of the units that were installed, certainly we see the potential. This is just palletizing, but we also want to explore the possibility of grabbing the packages and putting the package in the box. That's something that will be coming down the line. We'd like to get this done and then move on to explore those possibilities in the future.”

For Santana and the Mi Rancho team, automation is not about removing people. They see it as an essential path to grow their business while also helping their people.

“We're continuing to automate other manual tasks to stay competitive and manage rising labor costs, with a focus on ROI and safety”, said Santana. “By installing the latest automated equipment, we can produce more and transition repetitive jobs to roles like machine operators and mixers. It's not about reducing positions; it's about becoming more efficient and competitive."