GreenSeed Contract Packaging was founded in 2009 in Batavia, IL, and manages packaging operations for large and middle-market consumer packaged goods companies. With a focus on natural foods and sustainability, they pride themselves on supporting their customer brands with exceptional standards and service. With an eye toward the future, GreenSeed is always looking for opportunities to innovate and advance production lines to address inevitable supply chain disruptions, ensuring brands get products to market on time and with high integrity.

GreenSeed’s success has led to continued employee growth, upmarket channel expansion, and an award for their CEO, David Gray. In 2021, GreenSeed was awarded the Green Ole Award for its innovation in reducing waste and improving energy conservation operations for food manufacturers.

The Challenge

GreenSeed's skyrocketing production numbers have introduced both exciting opportunities and daunting challenges. While the company is reaching unprecedented levels of success, it must also continue to uphold its quality standards for a wide range of customer orders amid an industry-wide labor shortage, supply chain issues, and inflation.

Unfortunately, industry experts don’t expect labor shortages to improve anytime soon. Over the next decade, 4 million manufacturing jobs will likely be needed, and 2.1 million are expected to go unfilled if we do not inspire more people to pursue modern manufacturing careers.

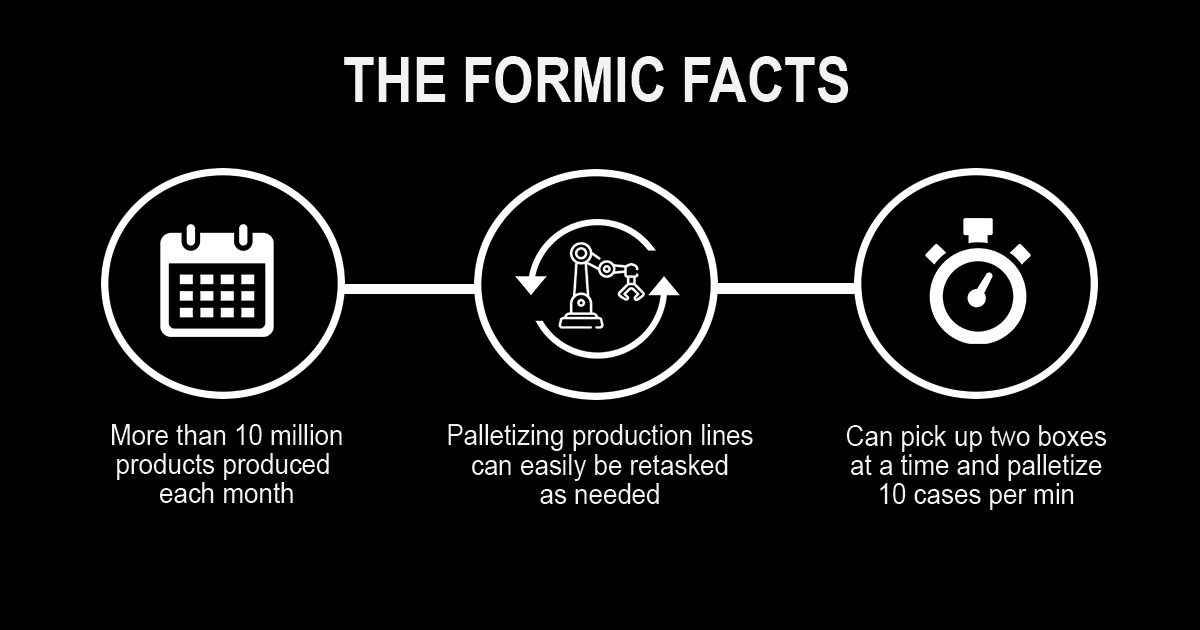

Unfortunately, the challenges don’t end there. Despite handling an impressive 10 million products during peak season, customers of contract packagers are often unwilling to commit long-term which can make automation investments difficult to justify and manage in such uncertain conditions.

David Gray, GreenSeed’s CEO, put it this way: “Our automation roadmap used to be heavily reliant on our clients, large global CPGs, where we needed a multi-year runway to build a process that could use robotics in manufacturing … When you’re thinking about investing in a system, you’re typically looking five years out, and I don’t think any CPG brands are interested in doing a five-year contract. They feel that there’s too much risk to locking in.”

On average, GreenSeed is changing over their production lines about once a week. Hector Leon, the Director of Operations, had been eyeing robotic automation for years as a solution to GreenSeed’s labor constraints, however, they had never actually taken the steps to invest. They had been waiting for the right partner and the right solution.

The Solution

They found that partner in Formic. The first step was to learn about GreenSeed’s customer mix and seasonality. Next, Formic’s team walked GreenSeed’s facilities to spot the opportunity for automation with the fastest and highest return on investment, which was palletizing.

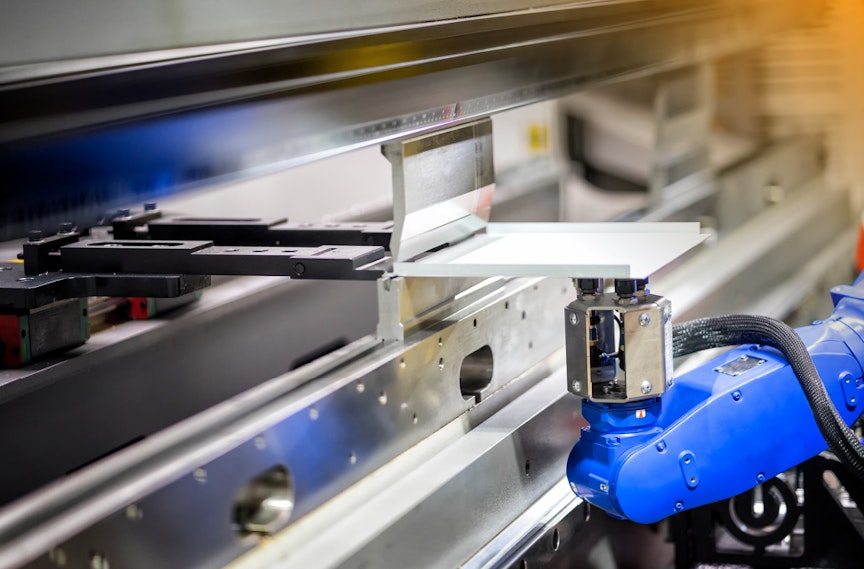

Formic then designed and deployed two customized collaborative palletizing systems on two different production lines that can be moved by the user to accommodate product changeovers.

GreenSeed was attracted to the idea of trying out automation technology without the typical capital outlay and assumption of risk. Added Hector Leon: “What was attractive about Formic was their concept. Paying by the hour and having the capability to try the technology out in small steps. There was really no downside.”

Since the system is priced based on usage and uptime, Formic and GreenSeed’s goals were in complete alignment: consistent, reliable production at the lowest possible cost, regardless of shifting product mix and volumes. Formic’s not in the business of selling equipment; it’s in the business of delivering outcomes.

Formic partnered with HCM Systems to maximize the performance of the FANUC CRX10iA/L robotic arm. Featuring state-of-the-art safety sensors and custom end-of-arm tooling, this system was designed with optimal throughput and floor space utilization in mind. Additionally, wheels are in motion to implement a system from Blueprint Automation to automate manual case packing and sealing processes prior to palletization - allowing even greater control over efficiency within production lines.

Each system is currently capable of handling 10 different SKUs, combined payloads of up to 17.5 pounds, and up to 10 cases per minute. When operating over two 10-hour shifts, this amounts to 12,000 cases each day!

The Impact

Gray envisions that the introduction of automation won’t impact the overall number of employees in the GreenSeed facility, but rather, change the nature of the work. “The vision is that the technology is going to help us be more competitive and serve as an educational platform for our people. We’re not looking to let anyone go, we’re looking to move them into better roles.”

Beyond immediate cost savings, GreenSeed’s customers are happy to see it adopting the latest automation technology. “Our customers have also given positive feedback when they are on-site and see the Formic systems. They like to see that we are using technology to advance our operation for them. They want to see us keep taking things to the next level,” added Leon.

“I don’t think there was a single company that wasn’t impressed by what we are doing, and looking across the board, they had a lot of comparisons,” said Gray of GreenSeed’s customer base. “Not many co-packers are embracing new technologies and taking that next step forward. So our adoption of automation showed the market what we’ve said: GreenSeed thinks differently about who we are and what role we play in the supply chain.”

Automating has also brought a morale boost to GreenSeed’s employees. “I remember the first day when the Formic system was installed. They were looking over at the robots in awe, asking if they could take pictures, and they were really excited to tell their families about this new technology that they got to work with. They were so happy,” said Leon.

“When we brought in the new technology, I think our employees were just amazed. There was this ‘wow’ moment. We weren’t met with fear at all,” added Gray.

Most importantly, with Formic, GreenSeed can instantly scale its automation efforts without relying on slow capital budgeting cycles. The traditional method of purchasing and deploying custom automation systems across multiple lines can take years, and in many cases, simply doesn’t happen. As Gray sees it, Formic has really leveled the playing field: “This really centralizes and democratizes robotics in a way we’ve never seen before in manufacturing.”

Download the Free Guide: How to Get Started with Robotic Automation

Automating with Formic, the only question manufacturers need to ask themselves is: what repetitive manual tasks can be automated in my facility right now?